Chrysanthemum mesh belt dryer

Energy conservation and emission reduction start from the heart, and scientific development is put into practice! JUSUNG has been committed to technology research and development and product building in the Food, Metallurgy, Chemical industry, Textile, Agriculture and Animal husbandry field since its establishment, and has accumulated to provide industry recommendation [Chrysanthemum mesh belt dryer] products for many customers!

Introduction of chrysanthemum dryer

Chrysanthemum is a perennial herb in the asteraceae family, usually used as medicine for its dry inflorescence. Fresh chrysanthemum has a high water content, among which the petal part has less water content, the organization is tender and easy to dry, and the flower head part has a huge water content, up to more than 80%, and the organization is older, and it is not easy to lose water, that is, chrysanthemum flower head is a kind of medicinal materials with very uneven organization. Dried chrysanthemum is mostly used for tea drinking, with a strong and sweet taste, greasy digestion, awakening brain and god functions. Therefore, the color, fragrance, shape and taste of chrysanthemum are very demanding, requiring primary color, original flavor and original after drying, which requires drying after ripening, strong drying of the pyrene head part, and weak drying of the petal part. At present, the traditional drying process of steaming and drying is not only dependent on the weather, but also causes excessive drying of petals and falling off of petals, and the quality of dried chrysanthemums cannot meet the requirements.

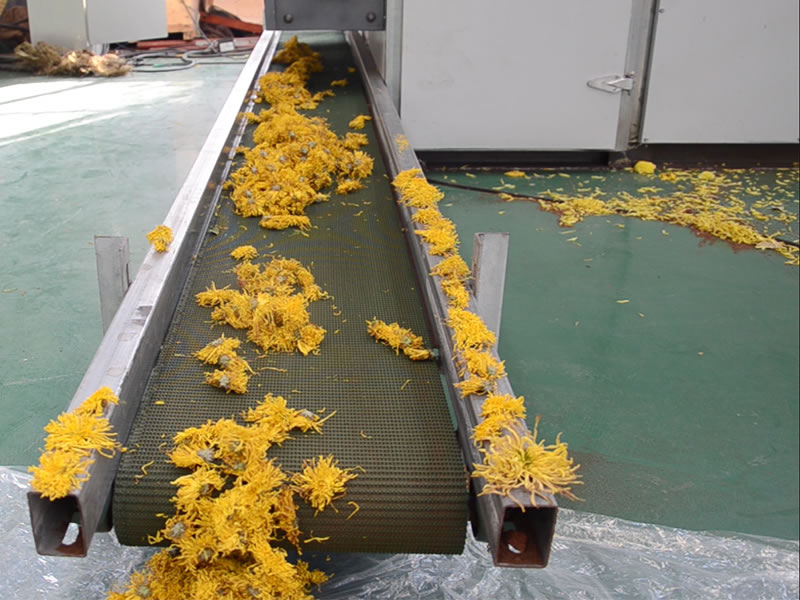

Chrysanthemum drying using mesh belt dryer can achieve mass and continuous production of wild chrysanthemum, fast drying speed, large output, low operating cost, drying process is not affected by the weather, easy to operate, and maximize the retention of product nutrition and color. It has greatly changed the situation of small output and poor quality in the past.

Chrysanthemum drying equipment is composed of feeding system, drying system, heating system and discharging system, including feeding conveyor, homogenizer, drying host, discharging conveyor, big fan, small fan, heat source, transmission motor and control cabinet. The chrysanthemum moves layer by layer in the drying box, and there are many flipping and falling processes, so that the chrysanthemum is heated more evenly.

Product advantage of Chrysanthemum mesh belt dryer

1. Large output: The dryer adopts multi-layer cyclic dynamic drying mode, which can be processed 24 hours by mass drying.

2. High quality: the dried chrysanthemum has bright color, complete shape and moderate moisture, which is trusted by users.

3. Intelligent and accurate: knowledge determines judgment, and the use of intelligent control system can ensure the temperature, time, air volume and other parameters control in the drying process.

4. cost saving: only one person can complete the whole equipment, drying time is also shortened, saving labor and time cost.

5. high heat energy conversion rate: more understanding early decision, product knowledge points: independently developed heat exchange device, can be matched with a variety of heat sources, the heat energy conversion rate is as high as 95%.

6. clean health: the whole drying process is completed in the closed box, will not be polluted by the outside world.

7. long equipment life: know more early decision, dryer overall running speed is very slow, almost no wearing parts, in normal use, service life as long as ten to fifteen years or more.

Working principle of Chrysanthemum mesh belt dryer

1. The heat source provides heat, and the cold air is introduced by the induced draft fan. The cold air is heated into hot air after the heat exchanger of the heat source part, which is sent into the dryer to air dry the material.

2. make decisions with knowledge, customers should understand this: the material from the conveyor belt on the material sharing mechanism flat to the net belt, in the dryer is "S" shape operation; The hot air generated by the induced draft fan is evenly dispersed in the dryer. Because the lower pressure is greater than the upper pressure, the hot air moves up naturally and passes through each layer of mesh belt, making the material fully contact with the hot air to achieve the purpose of drying.

Technical parameter of Chrysanthemum mesh belt dryer

|

Dryer model number |

Spreading area |

Handling capacity |

Total power |

Floor area (length * width * height) |

|

2×6 meters×4 layers |

40㎡ |

3tons |

15kw |

20*5*3.5meters |

|

2×8 meters×4 layers |

56㎡ |

5tons |

23kw |

22*5*3.5meters |

|

2×10 meters×4 layers |

72㎡ |

7tons |

28kw |

26*5*3.5meters |

|

2×12 meters×4 layers |

88㎡ |

9tons |

37kw |

28*5*3.5meters |

|

2×15 meters×4 layers |

112㎡ |

12tons |

64kw |

31*5*3.5meters |

|

2×20 meters×4 layers |

152㎡ |

15tons |

86kw |

36*5*3.5meters |

|

2.5×12 meters×6 layers |

165㎡ |

16tons |

55kw |

30*6*3.5meters |

|

2.5×15 meters×6 layers |

210㎡ |

18tons |

75kw |

33*6*3.5meters |

|

2.5×20 meters×6 layers |

285㎡ |

22tons |

103kw |

38*6*3.5meters |

|

2.5×25 meters×6层 layers |

360㎡ |

25tons |

108kw |

43*6*3.5meters |

|

2.5×30 meters×6 layers |

435㎡ |

30tons |

130kw |

48*6*3.5meters |

|

Note: Coal or biomass is used as heat source, and chili is used as raw material. |

||||

Poverty alleviation and comprehensive well-off society. Brand achievement is not the pursuit of JUSUNG people. How to make JUSUNG [Chrysanthemum mesh belt dryer] innovative create greater customer value and provide innovative products for the society is the direction that JUSUNG people are committed to pursuing!